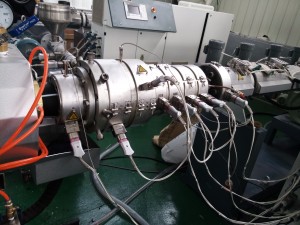

Feature of our PE PP PPR multi-layer pipe making machine: 1,The main machine adopts screws specially used for polyolefin. Equipped with auto vacuum charger and auto constant temperature dryer hopper, it possesses features of high production, good plasticization and stable extruding.

Feature of our PE PP PPR multi-layer pipe making machine: 1,The main machine adopts screws specially used for polyolefin. Equipped with auto vacuum charger and auto constant temperature dryer hopper, it possesses features of high production, good plasticization and stable extruding. 2,Die heads of helical type and basket type are perfect for polyolefin, and can help to produce sound melting pressure, and improve the plasticization capacity. Meanwhile, stable material-flow and pressure grade can be guaranteed.

3, Advanced vacuum calibrating method improves the cleanliness and hardness of surface. Reasonable high-speed sprinkling cooling water tank guarantees the pipe quality and high speed stable extruding.

4,Caterpiller of the hauling machine adopts anti abrassion alloy material, which realizes stable traction, wide frequency adjustment range and long lifespan.

5,New generation auto dust-free cutting blade realizes smooth cutting secant, high precison and low noise.

Models:

| Model | SJ65/33 | SJ75/33 | SJ90/33 | SJ120/33 |

| Pipe diameter | 16-63mm | 75-250mm | 110-450mm | 315-630mm |

| Marking line | SJ30 | SJ30 | SJ30 | SJ30 |

| Output capacity | 100kg/h | 150-200kg/h | 300-450kg/h | 500-700kg/h |

2, co-extruder: SJ30 extruder for marking line

2, co-extruder: SJ30 extruder for marking line  3, die head: different size may use different die head

3, die head: different size may use different die head  4, vacuum cooling tank: 6 meter length

4, vacuum cooling tank: 6 meter length  5, spraying water tank: 6 meter length, for big diameter, we may need to equip 2 sets or 3 sets of spraying water tank

5, spraying water tank: 6 meter length, for big diameter, we may need to equip 2 sets or 3 sets of spraying water tank  6, haul off machine: for different diameter, we may equip different type of haul off machine, such as double caterpillar type, three caterpillar type, four caterpillar type

6, haul off machine: for different diameter, we may equip different type of haul off machine, such as double caterpillar type, three caterpillar type, four caterpillar type  7, cutting machine: high quality cutting machine for non-dust cutting

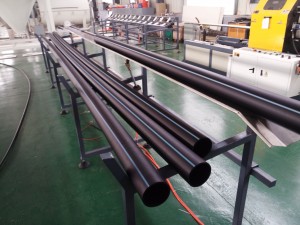

7, cutting machine: high quality cutting machine for non-dust cutting  8. product stacker: 6 meter length

8. product stacker: 6 meter length